Utilization of Waste Rubber Tires In The Subbase Course Of Road

Written by A. Sujaatha, Malini M, and Pradeepa R

The utilization of rubber tire waste in the subbase course of road construction presents an innovative and sustainable approach to address both waste management and pavement engineering challenges. This project aims to explore the feasibility and benefits of incorporating whole discarded rubber tires in the subbase layer of roads with a focus on evaluating the performance, durability, and environmental impact of this alternative approach. This project addresses its advantages, such as improved recycling, reduced construction costs, and enhanced sustainability, while emphasizing the need for proper planning, design, and construction techniques to ensure successful implementation. The findings of this project provide valuable insights into the technical viability, performance, and environmental implications of incorporating rubber tire waste in the subbase layer of roads, as well as the ways in which this strategy will advance sustainable road construction practices, waste management strategies, and the achievement of relevant sustainable development goals. This research serves as a foundation for future studies and provides guidance for policymakers, engineers, and stakeholders in the road.

Chapter 1

Introduction

The increasing number of vehicles globally, particularly in rapidly developing countries, has contributed to a higher demand for rubber tires. This growth of the automotive industry has led to a corresponding increase in tire production, resulting in a larger volume of tire waste. The recycling infrastructure for rubber tires is often inadequate, especially in developing countries. Recycling facilities require specialized equipment and procedures to handle and process tires effectively. The lack of proper infrastructure and investment in tire recycling has hindered the ability to manage and recycle tire waste efficiently. In some regions, there may be a lack of awareness among consumers and businesses about the importance of proper tire disposal and recycling. Insufficient regulations or enforcement regarding tire management can lead to improper disposal practices, such as illegal dumping or landfilling, exacerbating the tire waste problem.

Potholes are depressions or cavities in the road surface caused by the deterioration of the pavement. They often occur due to factors such as water infiltration, freeze thaw cycles, heavy traffic loads, and inadequate maintenance. Potholes can lead to vehicle damage, accidents, and discomfort for road users. If the subgrade soil of a road has low permeability, it can impede proper drainage of water from the road structure. Water accumulation in the subgrade can weaken the soil, reduce its load-bearing capacity, and contribute to instability and deterioration of the road. Weak subgrade soils have a lower bearing capacity, which means they are unable to support heavy loads. This can lead to structural damage, such as cracking or deformation of the road surface (“potholes”), particularly in areas with high traffic volumes or heavy vehicles. Addressing these problems caused by poor soil in the subgrade requires appropriate soil stabilization techniques, such as soil replacement, chemical stabilization, geosynthetics, or ground improvement methods. Properly assessing the subgrade soil conditions and implementing suitable engineering solutions can help mitigate these issues and ensure the long-term performance and durability of the road. After considering these problems, we decided to create a new innovative road pavement by laying whole discarded tires in subbase of the road.

1.1 Scope

The scope of the project is to improve road drainage through the utilization of discarded rubber tires, which have void spaces within that facilitate better water drainage, reducing the risk of water accumulation and potential damage to the pavement. The use of rubber tires also increases resilience, as rubber tires provide flexibility, which can help absorb and distribute stresses from traffic loads, reducing cracking and pavement failures. The utilization of discarded rubber tires as a construction material also helps reduce the environmental impact of tire disposal, promoting recycling and waste management efforts.

1.2 Literature Review

'Tires as sub-base in road' by Ankit Srivastav, Kartikey Mishra. The stones used as aggregates in this study are contained by the cell shape of the tires. Unpaved roads require less maintenance mainly due to the way that they behave in the presence of water. On an unpaved road with discarded tires as a sub-base, this degradation process ends at the wear surface. Rainwater can cause the compacted surface to deteriorate because it relies on the friction of the particles for its strength. The disadvantage here is that whole tires can hinder proper drainage within the sub-base layer. The tire cavities may impede the flow of water, leading to water accumulation and reduced soil stability. Poor drainage can negatively impact the performance and longevity of the road, leading to increased maintenance needs and potential damage.

'Reduction of subgrade fines migration into subbase of flexible pavement using geotextile' by Kishan Rai, Harsh Srivastav. This study found that under cyclic traffic conditions, the migration of subgrade fines into the subbase was significant. The number of fines that migrated to the subbase was approximately 6.39% in tests without geotextile, and this reduced to 1.81% in the test with geotextile. The geotextile layer acts as a barrier, preventing the fines from moving upwards and adversely affecting the performance of the pavement layers. One caveat is that the long-term durability of the geotextile layer is important for its effectiveness. Factors such as UV exposure, chemical exposure, and mechanical stresses can impact the durability and lifespan of the geotextile.

'A Review Study on Stabilization of soil by waste tyre rubber' by Satyam Kumar Gupta, Shubham Siddhu. This paper presents the stabilization of soils using rubber crumbs at varying percentages (5%, 10%, 15% and 20%). The samples were subjected to California bearing ratio, unconfined compression tests, and falling head permeability tests. The test results clearly show a significant improvement in the shear strength and bearing capacity of the studied soil, as well as vast increases in the soil’s permeability. It was also observed that there were decreases in OMC and MDD with increases in the percentage of rubber crumbs present in the soil. One of the significant advantages here is that it provides a solution to the challenge of rubber tire waste disposal. However, there can be potential environmental concerns associated with the leaching of chemicals from the rubber into the surrounding soil and groundwater.

Chapter 2 - Materials and Machinery Used

2.1 Soil

The pavement’s lowest layer subgrade consists of soil, which is dug and compacted by road rollers to strengthen the pavement.

Figure 2.1.1: Soil.

2.2 Rubber Tire Waste

The primary material for this project is rubber tire waste. This can be sourced from used or discarded tires, which are processed and prepared for use in the subbase course. As we know, rubber tires do not decompose. Here, tires that are thrown into junkyards after use are repurposed in a beneficial way: road construction. This strengthens the road and reduces the consumption of aggregates.

Figure 2.2.1: Waste rubber tire.

2.3 Aggregates

Aggregates are used in different layers of the road construction. They may include crushed stone, gravel, or recycled previous aggregates. Aggregates provide stability, load-bearing capacity, and proper drainage characteristics. Aggregate surface textures can increase the skid resistance of asphalt pavements, and large particle sizes can increase its ultimate load capacity. Sharp, angular aggregate textures can lend certain strength characteristics to concrete, while more rounded shapes can help it flow into confined spaces during placement.

Figure 2.3.1: Coarse aggregate.

2.4 Bituminous Materials (for Asphalt Pavements)

In the case of asphalt pavements, additional bituminous materials such as asphalt emulsion, asphalt binder, or asphalt additives may be required for the construction of the surface and binder courses. Flexible pavements contain bitumen or asphalt layers as a wear-prevention and load-supporting measure. An overall bitumen mix is used in the construction of flexible pavement to improve structural strength, surface drainage, and surface friction. The primary purpose of these bitumen mixes is structural strength provision. This involves even load dispersion throughout the layers of the pavement. Both dynamic and static loads are transferred to the base subgrade through the aggregate course.

2.5 Construction Machinery and Equipment:

In the case of asphalt pavements, additional bituminous materials such as asphalt emulsion, asphalt binder, or asphalt additives may be required for the construction of the surface and binder courses.

- Excavators: Excavators are commonly used in road construction for excavation, earthwork, and leveling tasks.

- Graders: Graders are used for leveling and shaping the road surface to achieve the desired cross sectional profile and smoothness.

- Rollers: Rollers are essential for compacting the different layers of the road, including the subbase course, to ensure proper density and stability.

- Dump Trucks: Dump trucks are used for transporting and delivering materials such as aggregates, soil, and asphalt to the construction site.

- Pavers: Pavers are utilized for placing and spreading asphalt or concrete materials during the construction of the surface and binder courses.

Chapter 3 - General and Methodology

3.1 Layers of the Pavement

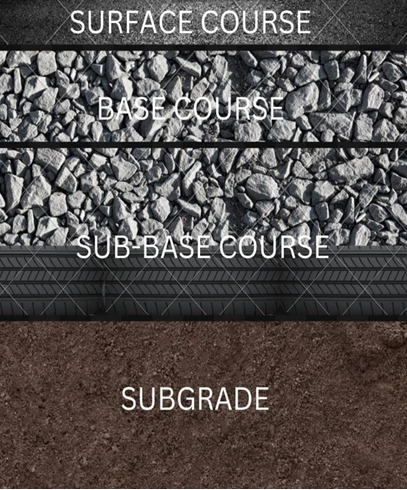

Figure 3.1.1: Layers of pavement

Subgrade: The subgrade is the lowest layer of the pavement layer system and ultimately supports all other pavement component layers. The soil subgrade is a layer of natural or Selected soil (from identified borrow pits) fulfilling the specified requirements well-compacted in layers to the required thickness.

Sub-base Course: The Sub-base course is provided beneath the base course and functions the same way as the base course. Granular aggregates are used to construct sub-base courses. They generally consist of gravel and crushed stone. Here, we suggest the rubber tire to provide support, in addition to granular aggregates to fill voids.

Base Course: The base course is generally composed of granular material such as crushed aggregate, gravel, selected soil, or a mixture of selected soil and aggregate.

Surface Course: The surface course is the upper layer of the flexible pavement and provides the smooth, durable, abrasion-resistant characteristics of a good roadway, retaining adequate friction for road safety. It is normally made from bitumen bound aggregate.

3.2 Methodology

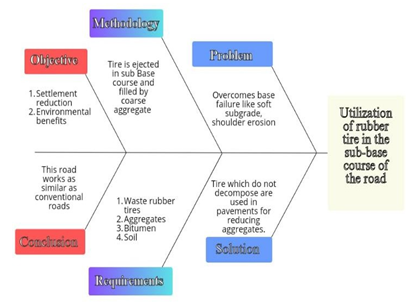

Figure 3.2.1: Methodology.

After connecting all the tires, developers fill the gaps with aggregates and compact them with the use of road rollers. They arrange tires in a row at the subbase course and make holes in the sides of the tire using a drilling machine. Then, they tie the tires together tightly.

3.3 Fish Bone Diagram

Figure 3.1: Fish Bone Diagram

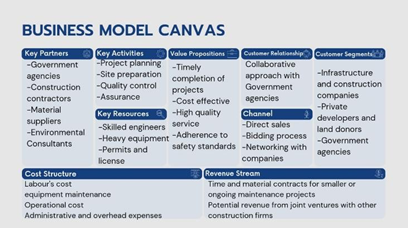

Chapter 4 - Business Model

4.1 Customized Business Model Canvas

Figure 4.1.1: Customized business model canvas

Continuous evaluation and reiteration are essential for the success of a customized business model. Regular review, feedback collection, and adaptation ensure that the model remains competitive and responsive to evolving customer needs and market dynamics. By developing a customized business model, businesses can leverage their unique strengths and resources to differentiate themselves in the market, deliver value to customers, optimize revenue generation, and achieve long-term growth and sustainability.

Conclusion

This investigation has highlighted that the primary beneficiaries of utilizing rubber tire waste in the subbase course are the road users themselves. The incorporation of rubberized subbase can result in a smoother and more comfortable road surface, reducing noise levels and vibrations experienced by vehicles. The utilization of rubber tire waste in road construction contributes to environmental sustainability and waste management. By diverting tires from landfills, it helps to reduce the environmental impact associated with tire disposal while promoting recycling. The road construction industry can benefit from incorporating rubber tire waste in the subbase course. It offers opportunities for innovation and alternative construction methods.References

- Pam Kasey (2009-01-15)"W.Va.Engineer Patents Way to Reuse Old Tires". The state Journal.

- Chakrey, A., & Pawar, P. (2015). Advantages of Mechanical Concrete Road over Conventional Road. International Journal of Innovative Technology and Exploring Engineering (IJITEE), 5(1), 43- 46.

- Kief, Ofer & Karpurapu, Rajagopal. (2008). Three Dimensional Cellular Confinement System Contribution to Structural Pavement Reinforcement. Mechanical Concrete®. WVDO.

- Justin Scott Smith, "Tire-Derived Geo- Cylinders and Polymer Products for Enhancing the Properties of Base/Sub base Materials in Pavement Systems" (2018). Graduate Theses, Dissertations, and Problem Reports. 3681.

- R. M. Subramanian and S. P. Jeyapriya, “Effect of Waste Tires in Flexible Pavement System”, in Indian geotechnical society Chennai chapter, students paper competition 2009.

- N.Tatlisoz, C.Benson and T.Edil, “Effect of fines on mechanical properties of soil- tyre chip mixtures.”, in ASTM STP 1275- 1997.

- Zornberg, J. G., Costa, Y. D. and Vollenweider, B. 2004b. Performance of prototype embankment built with tire shreds and nongranular soil.

- N.Tatlisoz, C.Benson and T.Edil, “Interaction between reinforcing geosynthetics and soil tyre chip mixtures”, Journal of geotechnical and geo environmental engineering, 124(11), 2001, pp. 1109 -1119.

- Hassona, Hassan, Marei, Hashem, “triaxial test and CBR test on shred tyre reinforced soil, concluded that The presence of shredded waste tyres”-2005.

- Prasad, Prasada Raju, Ramana Murthy (2008) ‘Use of Waste Plastic and Tyre in Pavement Systems’, IE(I) journal-CV, Vol.89, pp 31-35.

- Bosscher, P. J., Edil, T. B. and Eldin, N. (1992) Construction and performance of shredded waste tyre test embankment, Transportation Research.

- Record No. 1345, Transportation Research Board, Washington, D.C., pp. 44–52.

- Bosscher, P.J. and Edil, T.B (1994), “Engineering Properties of Tyre Chips and Soil Mixtures”, Geotechnical Testing Journal, Volume – 17, No. 4, pp 453 – 454.

To view all articles in this issue, please go to November 2023 eNewsletter. For a downloadable copy, please visit the IEEE Smart Cities Resource Center.

To have the eNewsletter delivered monthly to your inbox, join the IEEE Smart Cities Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart cities. Older eNewsletter can be found here. To download full issues, visit the publications section of the IEEE Smart Cities Resource Center.