Smart Warehousing of Automotive Parts and Accessories Inventory Control and Management

Written by Benson Chen, Lily Chen, Gil Huang, Yu-Tien Cheng, and Ruby Yao

The role of Internet of Things (IoT) in smart manufacturing has transformed industries across the globe, and the automotive sector is no exception. As the world progresses towards urbanization and into Industry 4.0 implementation, the concept of smart cities is becoming increasingly important. Smart manufacturing of automobile parts integrated with IoT is particularly crucial in enhancing efficiency, sustainability, and connectivity within the automotive industry, contributing to smart transport and intelligent vehicle running across smart cities.

Introduction

The integration of IoT in the manufacturing process has revolutionized the automotive industry. IoT devices and sensors are embedded in various stages of production, providing real-time data that enables manufacturers to monitor, analyze, and optimize their operations. In the context of smart manufacturing, IoT facilitates V2X communication between machines, products, and systems [1].

When moving into Industry 4.0, smart manufacturing has revolutionized the production of automobile parts, paving the way for more efficient and innovative processes within the realm of smart transportation [2]. This transformative approach involves the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics to enhance the entire manufacturing lifecycle. Smart manufacturing in the automotive industry encompasses real-time data analytics, predictive maintenance, and collaborative robotics, ensuring a seamless and responsive production line [3]. Through interconnected systems and intelligent machines, manufacturers can optimize production workflows, minimize downtime, and enhance the precision and quality of automobile components. This not only leads to cost savings, it also contributes to the development of more reliable, sustainable, and interconnected smart transportation systems. As Industry 4.0 continues to evolve, smart manufacturing is poised to play a pivotal role in shaping the future of automotive technology, driving advancements in safety, efficiency, and overall transportation sustainability [4].

Smart manufacturing has been successfully used in a wide range of industry sectors across individual smart cities, such as healthcare [5], consumer electronics [6], transportation [7], user experience [8], and power/energy [9]. As a case study, we look at the reliability and efficiency assessments of suspension parts such as Tie Rod Ends, Rack Ends, Ball Joints, Stabilizer Links, and Control Arms, ensuring they are in good ranges to empower the product capability. These assessments can be realized using various AI techniques such as self-cognizant prognostics.

Smart Manufacturing

Strictly set quality standards enable products to be integrated into different types of vehicles, all while designing and optimizing the products to meet the demand for even the harshest road conditions [10]. To enhance manufacturing efficiency, we optimize the handling of parts and energy efficiency using prognostics and health management (PHM) approaches [11].

Automated warehousing also plays a pivotal role in revolutionizing smart automotive parts manufacturing, contributing significantly to increased efficiency and streamlined processes. In the context of smart manufacturing, automated warehouses utilize advanced AI and IoT technology solutions to efficiently manage inventory, handle materials, and fulfill orders [12]. This reduces human intervention and enhances accuracy and speed in the supply chain.

The integration of energy-efficient practices in smart automotive parts manufacturing facilities is also crucial for sustainability and cost-effectiveness. Implementing smart lighting, optimizing heating, ventilation, and air conditioning (HVAC) systems, and utilizing energy-efficient machinery helps minimize energy consumption [13], thereby lowering operational costs and environmental impact. By synergizing automated warehousing and energy-efficient practices, the automotive industry can achieve a more sustainable and agile manufacturing ecosystem, meeting the demands of an evolving market while reducing its ecological footprint [14].

IoT technologies contribute to improved quality control through continuous monitoring of manufacturing processes. Sensors can detect deviations from set standards, which ensures that defective parts are identified and rectified in real-time [15]. Moreover, the use of IoT technologies enhances the traceability of automobile parts, allowing manufacturers to trace the journey of each component throughout the production process and thus ensuring compliance with quality standards [16].

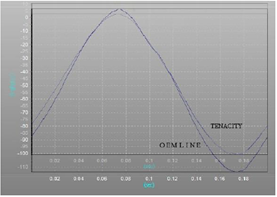

In addition, the initial digitalization when implementing IoT technologies eventually leads to the development of automated smart warehousing management systems and WCSs (Warehouse Control Systems), whose tens of thousands of sensors enable carts to carry more than 40,000 cartons of goods automatically inside of warehouses (70 meters long, 21 meters wide, and 15 meters high). An example of the quality control within a WCS is shown in Figure 1.

Figure 1: Quality control metrics

Smart warehousing systems can lower labor costs and enhance efficiency since less labor will be employed and this labor is operated by a system in 24 hours. Furthermore, productivity can be considerably boosted with enhanced controllability. A system can take advantage of the current production scale within a warehouse to produce more parts without adding any machines. With increased productivity, the whole supply chain benefits accordingly. Thus, the supply chain will be stabilized, leading to a larger supply of parts.

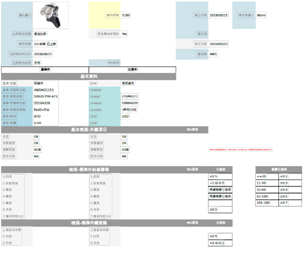

Figure 2: Smart warehousing automotive parts management

Simultaneously, an IoT technology system will work on the big data collected to analyze by itself (known as a “self-cognizant” system), as shown in Figure 2. This provides important insight into production runs so that the quantities produced can be varied. A smart warehousing system will also update data day by day so that stock can be adjusted flexibly to reflect demand in real-time. This optimizes production efficiently.

More importantly, all subcontractors utilized by a smart warehouse will be supplied according to accurate demand. In adhering to the data and reports generated by the system, they will not overproduce nor underproduce their stock. They will also be directed towards smarter and more efficient production practices [17]. Once the demand for smart production is high, subcontractors will have to optimize themselves. Tenacity within the smart system will help digitalize traditional factories for the production of the next generation. All parties will benefit from the optimized management and data analysis as it keeps the supply chain thriving and brings in more competition for the future.

Conclusion

Smart manufacturing extends beyond the factory floor and into the supply chain. IoT-enabled devices provide visibility into the entire supply chain, from raw material suppliers to the end product. This transparency allows for better inventory management, which reduces waste as it ensures that production is aligned with demand. As a result, manufacturers can respond swiftly to market changes and customer demands.

Smart warehousing promotes sustainability by optimizing energy consumption. IoT devices monitor energy usage and identify opportunities for energy efficiency, reducing environmental impact. This aligns with the goals of smart cities, which emphasize sustainable practices to create greener urban environments.

The implementation of smart manufacturing practices perfectly aligns with the vision of smart cities. The data collected from IoT devices in automobile manufacturing can be integrated into larger smart city systems. This interconnectedness allows for better traffic management, reduced emissions, and enhanced overall urban mobility.

References

- Fong, B., Fong, A. C., & Hong, G. Y. (2023). Sustainable Micromobility Management in Smart Cities. IEEE Transactions on Intelligent Transportation Systems.

- Hu, J., Kaur, K., Lin, H., Wang, X., Hassan, M. M., Razzak, I., & Hammoudeh, M. (2022). Intelligent anomaly detection of trajectories for IoT empowered maritime transportation systems. IEEE Transactions on Intelligent Transportation Systems, 24(2), 2382-2391.

- Tan, L., Shi, N., Yu, K., Aloqaily, M., & Jararweh, Y. (2021). A blockchain-empowered access control framework for smart devices in green internet of things. ACM Transactions on Internet Technology, 21(3), 1-20.

- Lv, Z., Zhang, S., & Xiu, W. (2020). Solving the security problem of intelligent transportation system with deep learning. IEEE Transactions on Intelligent Transportation Systems, 22(7), 4281-4290.

- Fong, B., Muhammid, U., Alhed, Z,, & Fong, A. (2024). A predictive analytics framework for big data in healthcare for Lady Health Worker (LHW) performance, IEEE Intelligent Systems.

- Goudarzi, S., Soleymani, S. A., Anisi, M. H., Jindal, A., Dinmohammadi, F., & Xiao, P. (2023). Sustainable Edge Node Computing Deployments in Distributed Manufacturing Systems. IEEE Transactions on Consumer Electronics.

- Tu, Z., Qiao, L., Nowak, R., Lv, H., & Lv, Z. (2022). Digital Twins-Based Automated Pilot for Energy-Efficiency Assessment of Intelligent Transportation Infrastructure. IEEE Transactions on Intelligent Transportation Systems, 23(11), 22320-22330.

- Mahmud, B., Hong, G., & Fong, B. (2023). A Study of Human–AI Symbiosis for Creative Work: Recent Developments and Future Directions in Deep Learning. ACM Transactions on Multimedia Computing, Communications and Applications, 20(2), 1-21.

- Lai, C. S., Locatelli, G., Pimm, A., Wu, X., & Lai, L. L. (2021). A review on long-term electrical power system modeling with energy storage. Journal of Cleaner Production, 280, 124298.

- Lv, Z., Li, Y., Feng, H., & Lv, H. (2021). Deep learning for security in digital twins of cooperative intelligent transportation systems. IEEE transactions on intelligent transportation systems, 23(9), 16666-16675.

- Fong, B., Kim, H., Fong, A. C. M., Hong, G. Y., & Tsang, K. F. (2023). Reliability Optimization in the Design and Implementation of 6G Vehicle-to-Infrastructure Systems for Emergency Management in a Smart City Environment. IEEE Communications Magazine, 61(8), 148-153.

- Akinsolu, M. O. (2022). Applied Artificial Intelligence in Manufacturing and Industrial Production Systems: PEST Considerations for Engineering Managers. IEEE Engineering Management Review, 51(1), 52-62.

- Fong, B., Fong, A., Hong, G., & Tsang, K. F. (2022). Optimization of power usage in a smart nursing home environment. IEEE Transactions on Industry Applications, 59(1), 38-46.

- Lai, C. S., Jia, Y., Dong, Z., Wang, D., Tao, Y., Lai, Q. H., ... & Lai, L. L. (2020). A review of technical standards for smart cities. Clean Technologies, 2(3), 290-310.

- Wang, K., Zhuo, L., Shao, Y., Yue, D., & Tsang, K. F. (2016). Toward distributed data processing on intelligent leak-points prediction in petrochemical industries. IEEE Transactions on Industrial Informatics, 12(6), 2091-2102.

- Fong, B., Fong, A. C. M., & Tsang, K. F. (2021). Capacity and link budget management for low-altitude telemedicine drone network design and implementation. IEEE Communications Standards Magazine, 5(4), 74-78.

- Lai, C. S., Jia, Y., Lai, L. L., Xu, Z., McCulloch, M. D., & Wong, K. P. (2017). A comprehensive review on large-scale photovoltaic system with applications of electrical energy storage. Renewable and Sustainable Energy Reviews, 78, 439-451.

This article was edited by Bernard Fong.

To view all articles in this issue, please go to November 2023 eNewsletter. For a downloadable copy, please visit the IEEE Smart Cities Resource Center.

To have the eNewsletter delivered monthly to your inbox, join the IEEE Smart Cities Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart cities. Older eNewsletter can be found here. To download full issues, visit the publications section of the IEEE Smart Cities Resource Center.