AI-based Power Optimization Scheme for Fishing Net Recycling

Written by Qi Xiang Zhang and Bernard Fong

Various smart city technology solutions play a vital role in the sustainability of a smart fishing village. One major safety hazard that needs to be urgently addressed is the improper disposal of worn fishing nets, which has become a significant environmental challenge leading to the pollution of marine ecosystems. To address this issue, energy consumption in recycling worn fishing nets can be optimized with artificial intelligence (AI). By leveraging AI technologies, we can enhance the efficiency and effectiveness of recycling processes, leading to a more sustainable and economical approach.

Introduction

The motivation for salvaging and recycling worn fishing nets extends to various important environmental and safety objectives. A system that properly treats worn fishing nets would meet several Sustainable Development Goals (SDG) were adopted by the United Nations in 2015 as a universal call to protect the environment, including SDG 6 (Clean Water and Sanitation), SDG 9 (Industrialization, Innovation, and Infrastructure), SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action) and SDG 14 (Conservation of Oceans ecology).

In SDG 6 (clean water and sanitation), our proposed methodology uses physical methods to clean discarded fishing nets. Compared with chemical methods, physical methods will not pollute water sources, and our latest physical methods can also reduce water consumption and achieve sustainable management of water resources.

In smart fishing villages, various technologies could enhance the safety and utilization of available natural resources. This work seeks to address the problems associated with water pollution and safety risks associated with vessels through the development of a new model. This model aims to solve the environmental pollution problems in a smart fishing village that is caused by abandoned fishing nets, improving the marine ecological environment, protecting marine biodiversity, and maintaining the sustainable development of smart fishing villages [1].

This paper therefore proposes an artificial intelligence (AI) solution that optimizes physical cleaning technologies that effectively remove pollutants from discarded fishing nets without the use of harmful chemicals while reducing negative environmental impacts, through an energy-efficient manner. The main objective is to transform discarded fishing nets into high-quality recycled nylon products, realize effective recycling and reuse of resources, reduce the demand for fresh raw materials, and reduce the environmental load of waste [2].

Worn Fishing Nets Recycling and Processing

Waste fishing nets, which can cause safety hazards to vessels if abandoned at sea, can be recycled in various ways to reduce their environmental impact [3]. Common methods for recycling fishing nets:

- Net collection and sorting: The first step is to collect discarded fishing nets from oceans, beaches, or fishing communities. Sorting is done to separate different types of nets based on their materials and condition.

- Manual sorting and cleaning: Once collected, the nets undergo manual sorting to remove any debris or non-recyclable components. This process helps ensure that only clean and suitable nets are used for recycling.

- Shredding: The nets are then shredded into smaller pieces using special machinery. Shredding breaks down the nets into manageable fragments, making it easier to process them further.

- Pelletization: The shredded net fragments can be further processed to create plastic pellets. These pellets can serve as raw materials for manufacturing new plastic products. The net fragments are melted and then extruded into small pellet shapes that can be used in various industries.

- Repurposing and upcycling: Instead of recycling the nets into raw materials, they can also be repurposed or upcycled into different products. For example, some organizations use old fishing nets to create recycled products such as bags, clothing, carpets, and furniture.

- Energy recovery: In cases where recycling or upcycling is not feasible, waste fishing nets can be used as a source of energy through processes like incineration or co-incineration. These methods generate heat or electricity by burning the nets in controlled environments.

While various industrial options are available for the treatment of worn fishing nets, recycling fishing nets is a complex process that requires collaboration between various stakeholders, including fishermen, recycling facilities, manufacturers, and environmental organizations [4]. Proper waste management practices and raising awareness about the importance of recycling can help reduce the negative impact of discarded fishing nets on marine ecosystems. We seek to address this environmental and safety problem through the development of an AI-based system for treating worn fishing nets in an energy-efficient manner.

Recycling worn fishing nets offers a compelling solution to mitigate the environmental impact caused by their improper disposal. By recycling these nets, we can reduce the demand for new materials and prevent the accumulation of waste in our oceans. However, traditional recycling processes often consume substantial amounts of energy and may not be optimized for efficiency.

An Energy-Efficient Process for Sustainability

The physical cleaning method is to form tiny bubbles in the liquid through physical cleaning in general water, and then make these bubbles burst on the surface of the object, resulting in strong impact and tiny eddy currents. This impact and swirl effectively remove dirt, grease, dust, and other contaminants from surfaces and tiny pores.

Physical cleaning has many advantages over the use of chemicals. First, it can clean into the hard-to-reach tiny pores and tiny crevices of the surface, thereby improving the cleaning effect. Second, it is a non-contact cleaning method that avoids scratches or damage to the surface of the object. In addition, it can complete the cleaning task in a short time and does not require the use of harmful chemical cleaning agents.

However, physical cleaning also has some limitations in that it has certain requirements on the material and shape of the object [5]. Certain materials may be less sensitive to such modalities or may be easily damaged by their effects. In addition, the effect will also be affected by the selection and temperature of the cleaning solution, so it is necessary to select a suitable cleaning solution and control the temperature during the cleaning process. Plastic recycling spinning technology is a method of converting recycled plastic waste into fibers for spinning. This technology helps reduce the amount of plastic waste and provides a sustainable alternative to the production of recycled fibers.

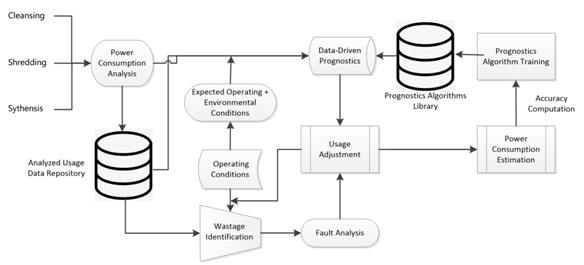

Figure 1: Framework for treating worn fishing nets in a smart fishing village.

Our proposed system, shown in Fig. 1, consists of the following processes:

- Collection and classification: First, plastic waste is collected and classified. We are now targeting all types of discarded fishing nets.

- Cleaning and treatment: Collected plastic waste is sent to treatment facilities for cleaning and treatment. The purpose of this step is to remove dirt, pollutants, and other impurities to make the plastic recyclable.

- Pulverization and melting: The cleaned plastic is pulverized into small particles or fragments, and melted by heating to make it into a plastic melt.

- Our proposed spinning methodology: Molten plastic is fed into the spinning machine to form continuous fibers through the process of spinning and stretching. These fibers can have different shapes and properties, which can be adjusted as needed.

To better utilize the recycled fibers produced, they can be mixed with other fibers to make recycled textiles, such as textile fabrics, carpets, ropes, etc. These recycled textiles can be widely used in clothing, household goods, automobiles, and other fields. The advantages of plastic recycling spinning technology include reducing the need for new plastic, reducing environmental impact, and providing a sustainable alternative. However, some of the challenges we have with this technology are also being overcome, including the need to sort and dispose of different types of plastics, as well as environmental issues such as gas and wastewater disposal that may be generated during processing.

Energy Efficiency Enhancement

One of the important aspects of our development is energy optimization. This is an important consideration in the industry as a vast amount of energy is required in processing fishing nets. Based on a self-cognizant prognostics scheme proposed in [6], Our system uses artificial intelligence in optimizing energy consumption as shown in Fig. 2.

Figure 2: Self-cognizant power usage optimization framework

Self-cognizant prognostics can optimize energy consumption in the recycling of worn fishing nets. It analyzes large datasets and identifies specific characteristics of fishing nets. By categorizing and sorting nets based on their composition, size, and material type, AI algorithms can streamline the recycling process and minimize energy waste.

Automated Sorting and Separation can also utilize AI-powered computer vision systems to identify and sort worn fishing nets based on their material composition. These systems can analyze images or videos of nets and distinguish between different types of materials, such as nylon, polyethylene, or polypropylene. By automating the sorting process, AI reduces the need for manual labor and minimizes errors, resulting in higher recycling efficiency and reduced energy consumption.

Another application of self-cognizant prognostics is recycling worn fishing nets through predictive maintenance of machinery. By monitoring and analyzing real-time data from recycling machinery [7], AI algorithms can predict equipment failures or malfunctions before they occur. This proactive approach allows for timely repairs and prevents unexpected downtime, ensuring optimal performance and reducing energy wastage.

The final step is to optimize the choice of recycling techniques for worn fishing nets. By analyzing the characteristics of the nets, AI algorithms can determine the most appropriate recycling methods, such as mechanical recycling, chemical recycling, or upcycling. This intelligent decision-making helps reduce energy consumption by selecting the most efficient and eco-friendly processes for each type of net.

By continuously collecting and analyzing data from the recycling process using machine learning, AI algorithms can identify patterns, detect inefficiencies, and propose optimizations. This iterative learning approach allows for ongoing energy consumption reduction and enhances the overall sustainability of the recycling operations. Given that the use case in a smart nursing home [8] has yielded an overall power saving of approximately 12% over a two-year period, enhanced AI algorithms should be able to enhance the energy consumption in the process of treating worn fishing nets.

Conclusion

The recycling of worn fishing nets is crucial for preserving marine ecosystems and minimizing environmental damage. By harnessing the power of AI, we can optimize energy consumption in the recycling process, making it more efficient and sustainable. Through automated sorting, predictive maintenance, energy-efficient techniques, and continuous learning, AI offers a comprehensive solution to minimize the environmental impact of worn fishing nets. Embracing these technological advancements can drive us toward a more sustainable future, where the fishing industry coexists harmoniously with the delicate balance of our oceans.

References

- Somayya, M., & Ramaswamy, R. (2016). Amsterdam Smart City (ASC): fishing village to sustainable city. WIT Transactions on Ecology and the Environment, 204, 831-842.

- Ottosen, L. M., Svensson, S. J., & Bertelsen, I. M. (2019). Discarded nylon fishing nets as fibre reinforcement in cement mortar. WIT Trans. Ecol. Environ, 231, 245-256.

- Bertelsen, Ida Maria Gieysztor, and Lisbeth M. Ottosen. "Engineering properties of fibres from waste fishing nets." In International Conference on Materials, Systems and Structures in Civil Engineering: Conference Workshop on Cold Region Engineering, pp. 7-16. 2016.

- Skvorčinskienė, R., Striūgas, N., Navakas, R., Paulauskas, R., Zakarauskas, K., & Vorotinskienė, L. (2019). Thermal analysis of waste fishing nets for polymer recovery. Waste and Biomass Valorization, 10, 3735-3744.

- Eimontas, J., Yousef, S., Striūgas, N., & Abdelnaby, M. A. (2021). Catalytic pyrolysis kinetic behaviour and TG-FTIR-GC–MS analysis of waste fishing nets over ZSM-5 zeolite catalyst for caprolactam recovery. Renewable Energy, 179, 1385-1403.

- Fong, B., Kim, H., Fong, A. C. M., Hong, G. Y., & Tsang, K. F. (2022). Self-Cognizant Prognostics for the Design and Implementation of Mission-Critical Telemedicine Systems under the Influence of Heavy Rainfall. IEEE Communications Magazine, 60(8), 80-84.

- Fong, B., Fong, A. C. M., & Hong, G. Y. (2022). Prognostics-Based Reliability Optimization for Consumer Healthcare Devices. IEEE Access, 10, 126885-126891.

- Fong, B., Fong, A. C. M., Hong, G. Y., & K. F. Tsang. "Optimization of Power Usage in a Smart Nursing Home Environment." IEEE Transactions on Industry Applications 59, no. 1 (2023): 38-46.

Keywords: Energy efficiency; maritime safety; product recycling; smart village

This article was edited by Bernard Fong.

To view all articles in this issue, please go to June 2023 eNewsletter. For a downloadable copy, please visit the IEEE Smart Cities Resource Center.

To have the eNewsletter delivered monthly to your inbox, join the IEEE Smart Cities Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart cities. Older eNewsletter can be found here. To download full issues, visit the publications section of the IEEE Smart Cities Resource Center.