Waste Fishing Net Regenerated Nylon and Recycling

Written by Jien Ming Wang, Steven Chao, Ken Chen

The vast amount of marine debris across fishing villages possess substantial threats to navigational safety of sea vessels, 90% of which are abandoned fishing nets. Abandoned fishing nets are discarded because they can no longer be used. Whether they sink to the bottom of the sea, entangle marine life, cover coral reefs, and cause ecological catastrophe [1]. Whether it is discarded as garbage, green recycling and proper recycling cannot be achieved. Modern fishing nets are mostly made of durable synthetic materials such as nylon and plastic, which are difficult to decompose in the natural environment [2]. Fishing nets drifting in the sea may entangle passing creatures; covering coral reefs will cause coral bleaching; they are also a threat to navigation because fishing nets may entangle the propulsion system of ships.

In addition to nylon (PA), common fishing net materials also include polyethylene (PE), polypropylene (PP) and polyethylene (PET), and are often composite. A fishing net typically consists of sinkers, floats and metal components. Therefore, the recycling process is complicated. In the past, recycling was mostly based on chemical recycling technology [3]. However, as chemical recycling technology becomes more sophisticated, pollution caused by the use of chemicals will also occur. Most plastic materials can be recycled and reused after being pre-processed and classified. Most of the fishing nets recycled are gill nets made of nylon with scientific name: polyamide (PA), which have high economic value for recycling [4]. Nylon is a synthetic polymer that takes hundreds of years to decompose, posing a severe threat to marine ecosystems. Discarded fishing nets, made predominantly of nylon, contribute to the vast problem of ghost gear; abandoned or lost fishing gear that continues to entangle marine life long after its use [5]. Ghost gear not only damages coral reefs and seafloor habitats but also poses a direct threat to marine animals and vessels.

Recycling as a Sustainable Smart Village Initiative

Making products with environmental protection and recycled materials has become the goal and pursuit of major brands around the world. Therefore, the recycling and recycling technology of recycled nylon sand from abandoned fishing nets is a project that can solve many problems and has gained favor.

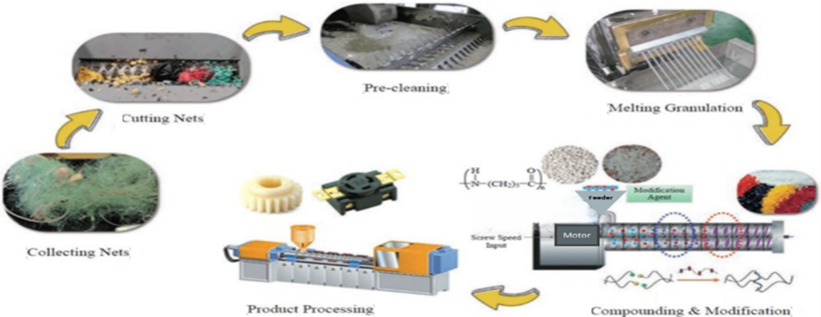

Our proposed technology of cleaning, crushing, melting, spinning into yarn, and making into clothing materials belongs to physical recycling because the polymerization form is not changed. Although it is not as efficient as chemical recycling, it does not produce the pollution of chemical recycling.

The recycling of waste fishing nets made from nylon represents a viable and eco-friendly solution to address the challenges posed by discarded fishing gear. By collecting and recycling these nets, we can reduce the amount of plastic entering the oceans, minimize the impact on marine life, and promote sustainable smart fishing village through:

- The source of waste gas fishing nets is safe: providing a stable source of fishing nets for the recycling of domestic and foreign abandoned fishing nets, mainly in adjacent sea areas, successfully reducing the carbon footprint by 4,100.687 grams, further promoting environmental protection, as shown in Fig. 1.

Fig. 1: Nylon Lifecycle

2. Circular economy: Recycle discarded fishing nets and apply them to plastic material draw spinning technology, which is applied to various material fields. Reduce your carbon footprint even further. Recycling nylon from waste fishing nets reduces the demand for new raw materials. This helps conserve natural resources and decreases the environmental impact associated with the extraction and production of reusable nylon.

3. Physical cleaning technology: The use of physical cleaning technology combined with the development of environmentally friendly cleaners can effectively clean abandoned fishing nets and remove dirt and harmful substances. Our proposed methodology does not require the use of large amounts of harmful chemicals, and the research and development is environmentally friendly. The cleaning agent will comply with the EU Zero Discharge of Hazardous Chemicals (ZDHC) certification and Restricted Substances List (RSL) specifications. This cleaning technology is an environmentally friendly and efficient way to ensure that water is not contaminated.

Energy Efficiency

Solar power generation: Integrating green power and using solar power as a renewable energy supply can provide clean energy for the efficient recycling, reduce dependence on traditional energy, and further reduce carbon emissions. The production of nylon from recycled materials typically requires less energy than the production of new nylon. This results in lower greenhouse gas emissions, contributing to efforts to combat climate change.

Waste heat reuse: Utilizing boiler steam power generation to provide small-scale heat energy can maximize the use of energy and improve energy utilization efficiency [6]. By recycling and utilizing waste heat, energy waste can be reduced and effective use of energy can be achieved [7].

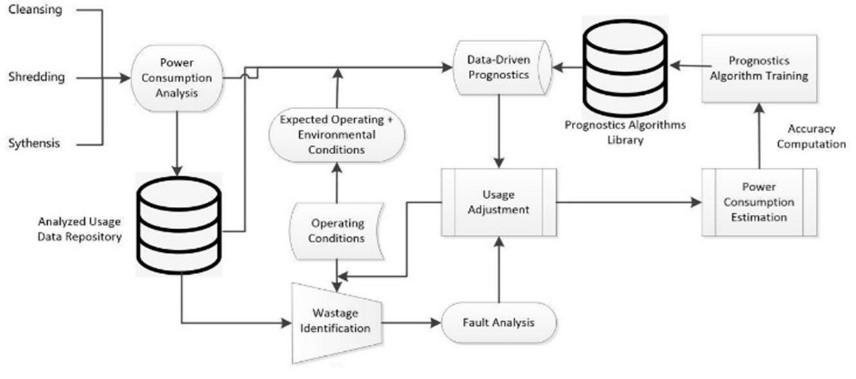

Power usage optimization technology utilizes AI and ML methods to make energy consumption more efficient and sustainable. For start, Load forecasting with machine learning algorithms to analyze historical energy consumption patterns and predict future demand [8]. This helps estimate peak usage periods, allowing them to optimize energy distribution and reduce wastage. Automate demand response by dynamically adjusting energy consumption in real-time based on the current load conditions [9]. Throughout the recycling facility, heating, ventilation, air conditioning (HVAC), lighting can be optimized based on occupancy patterns and weather conditions [10]. helping balance supply and demand for the best power usage methods by adopting a prognostics approach derived from [11] to optimize power usage efficiency as shown in Fig. 2.

Fig. 2: Prognostics in energy optimization.

A Summary of Nylon Recycling Techniques

Nylon is a type of synthetic polymer that can be recycled, and there are various methods for recycling nylon materials:

Mechanical Recycling: Involves collecting, cleaning, and melting down nylon waste to produce new nylon products. This method is applicable to post-industrial waste, such as manufacturing scraps, as well as post-consumer waste like discarded clothing [12].

Chemical Recycling: Involves breaking down nylon polymers into their monomer units through chemical processes. This method can handle more complex nylon waste, including mixed or contaminated materials.

Nylon Depolymerization: Some advanced technologies aim to break down nylon into its original monomers using depolymerization techniques. This allows for a more efficient reuse of the monomers in the production of new nylon without the loss of material properties [14].

Biological Recycling: Uses enzymes to break down nylon into simpler components. As for smart recycling, this can encompass various technologies and approaches aimed at improving the efficiency and sustainability of recycling processes. Some potential elements of smart recycling using sensors to monitor the quality and composition of nylon waste, helping optimize the recycling process [16].

Analyzing data related to recycling processes to identify trends, optimize operations, and reduce waste as well as to optimize sorting processes and improve the overall efficiency of recycling operations.

References

- Gilman, E., Musyl, M., Suuronen, P., et al. (2021). Highest risk abandoned, lost and discarded fishing gear. Scientific Reports, 11(1), 7195.

- Peng, C., Tang, X., Gong, X., Dai, Y., Sun, H., & Wang, L. (2020). Development and application of a mass spectrometry method for quantifying nylon microplastics in environment. Analytical Chemistry, 92(20), 13930-13935.

- Chen, E., & Wang, J. M. (2023). Smart Energy-Efficient Waste Recycling: A Case Study of Treating Abandoned Fishing Nets, IEEE Smart Cities Newsletter, 5(6).

- Weissbach, G., Gerke, G., Stolte, A., & Schneider, F. (2022). Material studies for the recycling of abandoned, lost or otherwise discarded fishing gear (ALDFG). Waste Management & Research, 40(7), 1039-1046.

- Nama, S., & Prusty, S. (2021). Ghost gear: The most dangerous marine litter endangering ocean. Food Sci. Rep, 2(5).

- Wang, D., Xie, C., Wu, R., et al. (2021). Optimal energy scheduling for data center with energy nets including CCHP and demand response. IEEE Access, 9, 6137-6151.

- Yan, M., Wang, D., Lai, C. S., & Lai, L. L. (2021). A Review on Thermal Energy Modelling for Optimal Microgrids Management. Thermo, 1(1), 63-76.

- Lai, C. S., Yang, Y., Pan, K., et al. (2020). Multi-view neural network ensemble for short and mid-term load forecasting. IEEE Transactions on Power Systems, 36(4), 2992-3003.

- Fong, B., Fong, A., Hong, G., & Tsang, K. F. (2022). Optimization of power usage in a smart nursing home environment. IEEE Transactions on Industry Applications, 59(1), 38-46.

- Xu, X., Li, J., Xu, Y., et al. (2020). A two-stage game-theoretic method for residential PV panels planning considering energy sharing mechanism. IEEE Transactions on Power Systems, 35(5), 3562-3573.

- Fong, B., Fong, A. C., & Hong, G. Y. (2023). Sustainable Micromobility Management in Smart Cities. IEEE Transactions on Intelligent Transportation Systems, 24(12), 15890-15896.

- Mondragon, G., Kortaberria, G., Mendiburu, E., González, N., Arbelaiz, A., & Peña‐Rodriguez, C. (2020). Thermomechanical recycling of polyamide 6 from fishing nets waste. Journal of Applied Polymer Science, 137(10), 48442.

- Chanda, M. (2021). Chemical aspects of polymer recycling. Advanced Industrial and Engineering Polymer Research, 4(3), 133-150.

- Alberti, C., Figueira, R., Hofmann, M., Koschke, S., & Enthaler, S. (2019). Chemical Recycling of End‐of‐Life Polyamide 6 via Ring Closing Depolymerization. ChemistrySelect, 4(43), 12638-12642.

- Amaly, N., El-Moghazy, A. Y., Si, Y., & Sun, G. (2020). Functionalized nanofibrous nylon 6 membranes for efficient reusable and selective separation of laccase enzyme. Colloids and Surfaces B: Biointerfaces, 194, 111190.

To view all articles in this issue, please go to January 2024 eNewsletter. For a downloadable copy, please visit the IEEE Smart Cities Resource Center.

To have the eNewsletter delivered monthly to your inbox, join the IEEE Smart Cities Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart cities. Older eNewsletter can be found here. To download full issues, visit the publications section of the IEEE Smart Cities Resource Center.